Coop&Inno BIPV replaces color steel tiles and sets a new benchmark for green and energy-saving buildings.

Publish Time: 2025-05-06

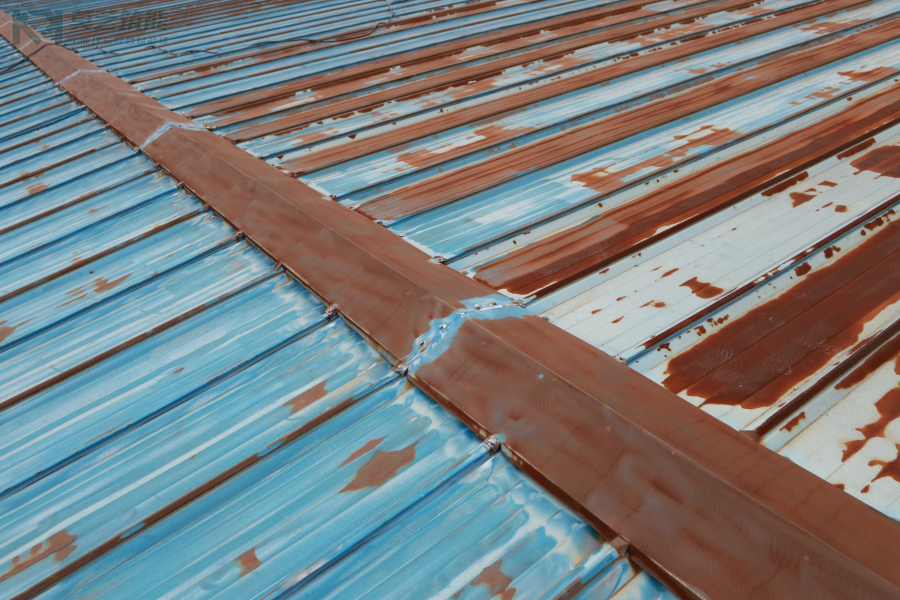

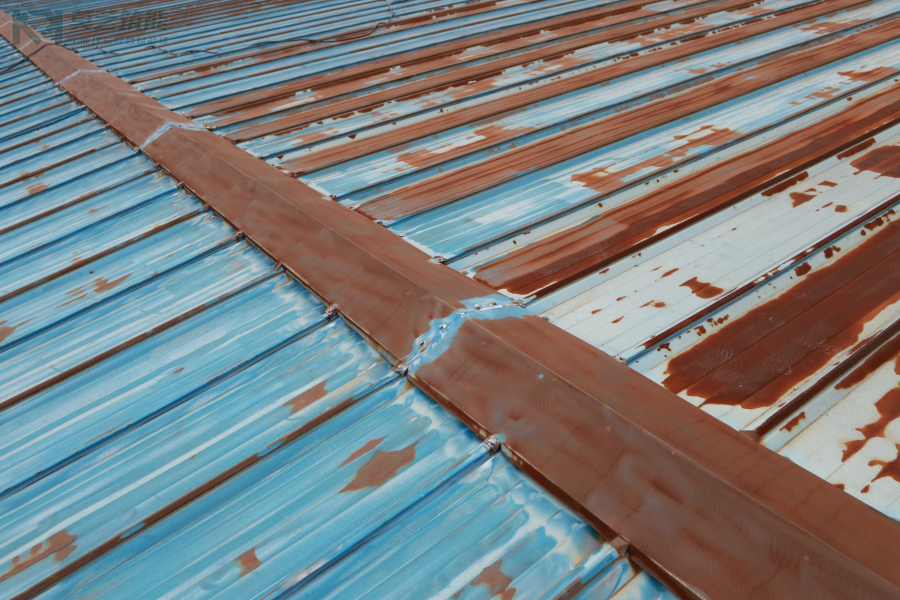

Color steel tile roofs are a common building material and are widely used in industrial plants, warehouses and other scenes. However, this type of building material also has the following disadvantages:1. The waterproof performance of color steel tile roofs is relatively poor. Because the joints are overlapped and fixed with screws, they are easily affected by thermal expansion and contraction after long-term use, resulting in aging and cracking of the sealant, and a high risk of rainwater infiltration.2. The corrosion resistance of color steel plates is relatively weak. In harsh environments such as acid rain and salt spray, the galvanized layer or color coating is easy to peel off and fail, and the steel will rust quickly when directly exposed to the external environment. The micro-battery effect generated by the contact between different metal accessories will accelerate corrosion. Scratches on the surface of the plate or insufficient anti-corrosion treatment of welding points will also form rust spots and gradually spread.3. The service life of color steel tiles is relatively short, usually only 10 to 15 years, which is much lower than traditional materials such as concrete tiles. Local repairs are difficult to completely solve the problem, and the entire tile needs to be replaced frequently, which will incur additional costs such as demolition and transportation. In addition, water leakage may also cause damage to interior decoration and dampness of equipment, resulting in a significant increase in comprehensive costs. Especially in coastal cities with severe salt fog, the life of color steel tiles is often less than 10 years. However, the unique advantages of the Copco Inno BIPV system can solve the pain points of color steel tile roofs: the exclusive patented product has obtained the TUV closed water test report, and there is no need to worry about water leakage. The entire waterproof system frame adopts an all-aluminum alloy design, which is more corrosion-resistant and has a longer service life, greatly reducing the cost of replacing tiles. In addition, the use of double-glass components has higher power generation efficiency. It can not only solve the pain points of color steel tiles, but also obtain additional power generation benefits.BIPV direct replacement of color steel tiles case and design ideas:

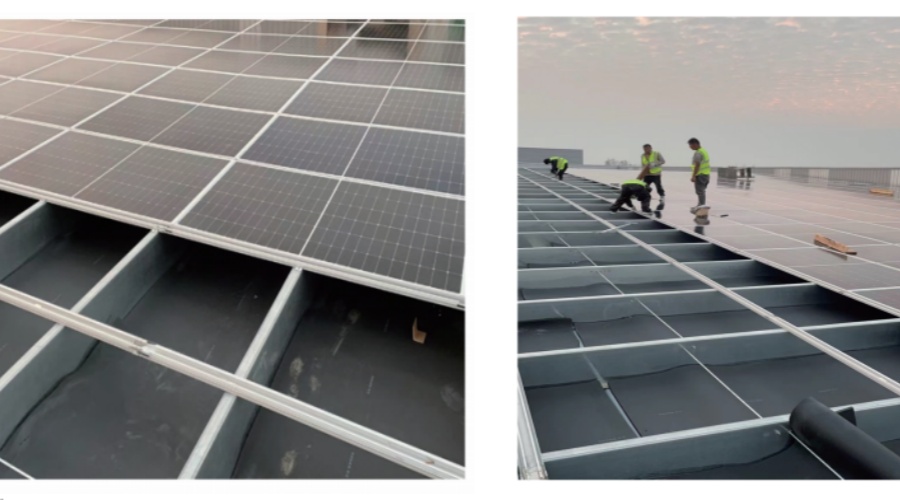

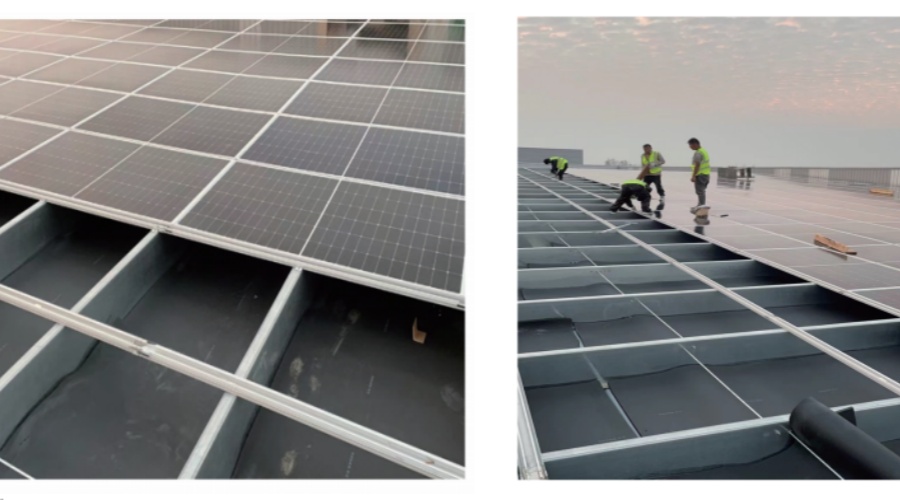

However, the unique advantages of the Copco Inno BIPV system can solve the pain points of color steel tile roofs: the exclusive patented product has obtained the TUV closed water test report, and there is no need to worry about water leakage. The entire waterproof system frame adopts an all-aluminum alloy design, which is more corrosion-resistant and has a longer service life, greatly reducing the cost of replacing tiles. In addition, the use of double-glass components has higher power generation efficiency. It can not only solve the pain points of color steel tiles, but also obtain additional power generation benefits.BIPV direct replacement of color steel tiles case and design ideas: Design concept:For newly built steel structure workshops:First, the best installation method is to install the color steel tile bottom tile under the purlin, and lay a fireproof and heat-insulating layer on the bottom tile, and lay the Copco Inno embedded BIPV waterproof system directly above the purlin to achieve the effects of waterproofing, heat insulation and power generation. Its advantage mainly lies in using the height spacing of the purlins to increase the ventilation space at the bottom, which plays a role in reducing the temperature of the photovoltaic panels and increasing the photovoltaic power generation.Secondly, the secondary installation method is to install the color steel tile bottom tile above the purlin, lay a fireproof insulation layer on the bottom tile, install a high support bracket above the insulation layer, and lay the Kupu Inno embedded BIPV waterproof system on the high support bracket to achieve the effect of waterproofing and insulation. This installation method is relatively optimized, with a small convection space and little impact on the power generation of the photovoltaic system.

Design concept:For newly built steel structure workshops:First, the best installation method is to install the color steel tile bottom tile under the purlin, and lay a fireproof and heat-insulating layer on the bottom tile, and lay the Copco Inno embedded BIPV waterproof system directly above the purlin to achieve the effects of waterproofing, heat insulation and power generation. Its advantage mainly lies in using the height spacing of the purlins to increase the ventilation space at the bottom, which plays a role in reducing the temperature of the photovoltaic panels and increasing the photovoltaic power generation.Secondly, the secondary installation method is to install the color steel tile bottom tile above the purlin, lay a fireproof insulation layer on the bottom tile, install a high support bracket above the insulation layer, and lay the Kupu Inno embedded BIPV waterproof system on the high support bracket to achieve the effect of waterproofing and insulation. This installation method is relatively optimized, with a small convection space and little impact on the power generation of the photovoltaic system. The waterproof performance and testing standards of the BIPV roof system, led by Jiangsu Kupu Inno Green Energy Technology Co., Ltd., set an industry benchmark. The team standard "Technical Specifications for Roof Waterproofing of Building Integrated Photovoltaic Power Generation System" (T/CI945-2025) was officially released in April 2025. Testing requirements: The depth of water accumulation in the frame around the roof should be no less than 150mm, and the water holding test time should be at least 48 hours. There should be no leakage or seepage on the back of the BIPV roof.

The waterproof performance and testing standards of the BIPV roof system, led by Jiangsu Kupu Inno Green Energy Technology Co., Ltd., set an industry benchmark. The team standard "Technical Specifications for Roof Waterproofing of Building Integrated Photovoltaic Power Generation System" (T/CI945-2025) was officially released in April 2025. Testing requirements: The depth of water accumulation in the frame around the roof should be no less than 150mm, and the water holding test time should be at least 48 hours. There should be no leakage or seepage on the back of the BIPV roof.